INITIAL PRODUCTION CHECK (IPC/IPI)

What is an Initial Production Check?

Initial Production Check, or IPC, is an inspection service of raw materials, components, and products that are carried out at the very beginning of product production. It is typically performed when 10-20% of your products have been produced.

When should you use Initial Production Check?

Initial Production Check helps to identify potential issues with your products during the very initial phase of the production stage. An Initial Production Check is the first step in ensuring product quality consistency throughout the whole production stage. It helps to verify first-run quality requirements, start your production on the right footings, and keep a consistent quality standard. You will be able to minimize wasted time, rework, and shipping delays that can happen at the later stages of your production.

We recommend you to use Initial Production Check on all kinds of products, especially when you are working with high-risk products and new factories.

How an Initial Production Check can help with your production and product quality issues?

- It ensures that you are using the right raw materials on your products.

- It ensures that the materials fulfill your quality standards.

- It ensures that the materials fulfill the regulatory standards.

- It streamlines your production process by detecting problems and rectifying defects during the early phases of production.

How does Initial Product Check work?

As per the product specification and approved samples provided, we will verify if the correct materials, components, and accessories have been ordered by the factory to your specifications.

In an Initial Production Check, we will also randomly select and inspect a sample of partially produced products for potential defects, then report our findings to you.

What Is The Initial Production Check Process?

1

Submit your production specification or approved samples

2

Our inspectors perform onsite inspection.

3

Inspection Report ready for you.

DURING PRODUCTION CHECK (DUPRO)

What is a During Production Check (DUPRO)?

A During Production Check (DUPRO) is an Inspection Service performed when 26-99% of your production is completed and hasn’t been packed for shipping. It is typically performed at 40-50% of the product stage.We are able to check all components, materials, and semi-finished parts according to your specification. They are inspected to avoid any possible defects before mass production. A DUPRO becomes a safety net and keeps your production on the right track.

Why perform During Production Check (DUPRO) ?

We will help you validate products being produced and you can ensure they continue to meet quality requirements. It uncovers production problems at a rather early stage. So you can have ample time to rectify production issues such as poor product quality, delayed production schedule, and more. It works for all kinds of products and is typically ideal for Medium Risk Products (E&E) and poorly performed factories.

How a During Production Check can help with your production and product quality issues?

To verify if the production schedule is on track to prevent delay.

To ensure product quality and specifications are in line with your requirements during the mass production stage.

To discover defects and nonconformities and avoid them developing into critical quality issues.

How does During Production Check work?

During Production Check keeps your production on track. In a During Production Check, inspectors verify the quality of your semi-manufactured or final products according to conformity and your product specification.

After inspection, you have visibility of whether the products meet your expectation. If there’re any defects, you are able to see them in the report and corrective actions can be taken to improve the production process.

Some of the standard specifications in During Production Check include product conformity, workmanship, visual, onsite functionality test, packaging, shipping mark, labels, etc.

What Is The During Production Check Process?

Our inspectors perform onsite inspection

Submit your production specification or approved samples

Inspection Report ready for you

PRE-SHIPMENT INSPECTION (PSI)

What is a Pre-shipment Inspection / Final Random Inspection?

A Pre-Shipment Inspection (PSI) or Final Random Inspection (FRI) is an inspection service that is conducted before shipment when your production is 100% completed and at least 80% packed.

When should you use Pre-shipment Inspection / Final Random Inspection?

Before you ship. We suggest you reserve ample time for a Pre-Shipment Inspection (PSI) or Final Random Inspection (FRI) according to your shipment schedule. The time to reserve really depends on

the risk you can take if the inspection result is a fail.

The time factory needed to take corrective actions.

Why should you use Pre-Shipment Inspection / Final Random Inspection?

A Pre-Shipment Inspection (PSI) or Final Random Inspection (FRI) is excellent insurance for your business and products before you ship. It is an effective inspection service to ensure the final products and packaging are in line with prescribed specifications. It safeguards your product against costly risks and helps you make an informed decision before releasing the shipment.

How does it work?

A Pre-Shipment Inspection (PSI) or Final Random Inspection (FRI) will choose a specific quantity of completed products according to AQL. Our qualified inspectors help you assess whether the final product meets all quality specifications (i.e. color, workmanship, label, function, fit, packaging of products, etc.) according to your standard.

What Is The Pre-Shipment Inspection / Final Random Inspection Process?

- Submit your production specification or approved samples

- Our inspectors perform onsite inspection

- Inspection Report ready for you

What is a Full Inspection?

Full inspection, also known as piece-by-piece product inspection or 100% product inspection, is a unique quality control process that helps ensure each product’s quality before shipping. Generally, Full Inspection focus on the workmanship and basic function of the products. We can also perform an on-site test according to the customer’s requirement. By inspecting each product piece by piece, a full inspection is simply the safest way to ensure a nearly 100% qualification rate and to spot any defect in your manufactured products. It helps to ensure that all quality control requirements of the products are met.

you can select among our service offer PSI, DUPRO, FRI and select the AQL 100%.

A full inspection focuses on the workmanship and cannot verify full parameters against the specification ( for example, dimension, drawing that may cover many dimensions. BV normally only check the overall size/dimension and in very limited sample size).

The final number of Man Day will be depending on the overall quantity of products. Our Team will advise you of the number of Man Day requested upon reception of your request.

For more information, please feel free to contact us.

Container Loading Check (CLC)

What is a Container Loading Check (CLC)?

A CLC is an onsite inspection that ensures your products have been manufactured correctly and that the actual ordered quantity of products is securely loaded onto your container or truck.

During a container loading check, Our inspector will select boxes at random to confirm that product quality matches the specifications and/or approved sample provided by the client. They will also check that each carton reflects the quantity of products ordered and that all packaging contains the correct barcodes, labeling and packing materials. On top of this, the inspector will also closely supervise the entire container/truck loading process.

Production Monitoring (PM)

What is production monitoring?

Production monitoring is a specialized on-site inspection performed to verify the production status and the inventory of raw materials.

An inspector examines your factory and checks the quantity of the raw materials and accessories required for your products before production. Detailed reporting for the entire or specific production cycle of your product will be carried out.

Why perform production monitoring?

Keep your factory accountable from start to finish of the production run

Maintain control and visibility of the entire production process

Detect the possibility of any sub-contracting

Early identification of production delays

Identify poor internal quality control from suppliers

Identify poor warehouse or production environment

Confirm if the factory’s declared production capacity is feasible

Production monitoring that is completed as a single intervention can only provide a general sense of the overall production status. When carried out consistently over a predetermined period i.e., weekly, the production status can be continuously followed up for a more accurate timeline and improved quality control.

SAMPLE COLLECTION

Sample Collection service (or Sample Picking service), in simple terms, is a quality control and inspection service to ensure that the samples being collected are accurate representations of mass production. The sample collected can be used for further review or testing.

Brands and retailers frequently use Sample Picking service to randomly select a small, representing sample batch before sending it for lab testing. It prevents the lab from only testing and approving pre-arranged samples from suppliers because they may not reflect the actual production.

As the world’s leading third-party inspection company, We offers a reliable Sample Collection service to ensure that authentic production samples are collected and delivered. Our team adheres to our integrity policy and follows rigid protocol for the whole sample-picking process.

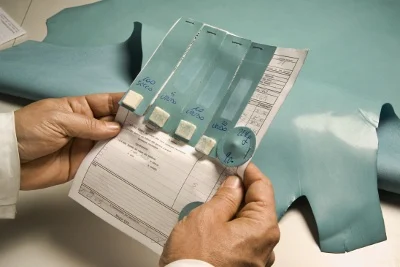

PSAI inspector handles the whole process by picking random samples, verifying specifications, and sealing the samples at the factory. In most cases, after samples are sealed, the factory can dispatch the samples to the lab or client’s office for further handling.

Fresh Production Inspection

Quality Control Tailored for the Produce Industry

Fresh produce is a sensitive product category that requires fast shipping and proper storage. Any delay in your supply chain or a disruption in storage conditions can seriously impair your product’s quality. For a fresh produce supplier, it is equally important to check the condition of their inventory at departure from the farm or packaging facility and upon its arrival at the destination.

We offers product inspections for your produce, helping you receive an accurate picture of your merchandise every step of the way. We will check the quality of your produce before it’s shipped, and will be at your destination to inspect it again after transit.